INTEGRATED SOLUTION

Multiple-Element Gas Container (MEGC) with Semi-Trailer

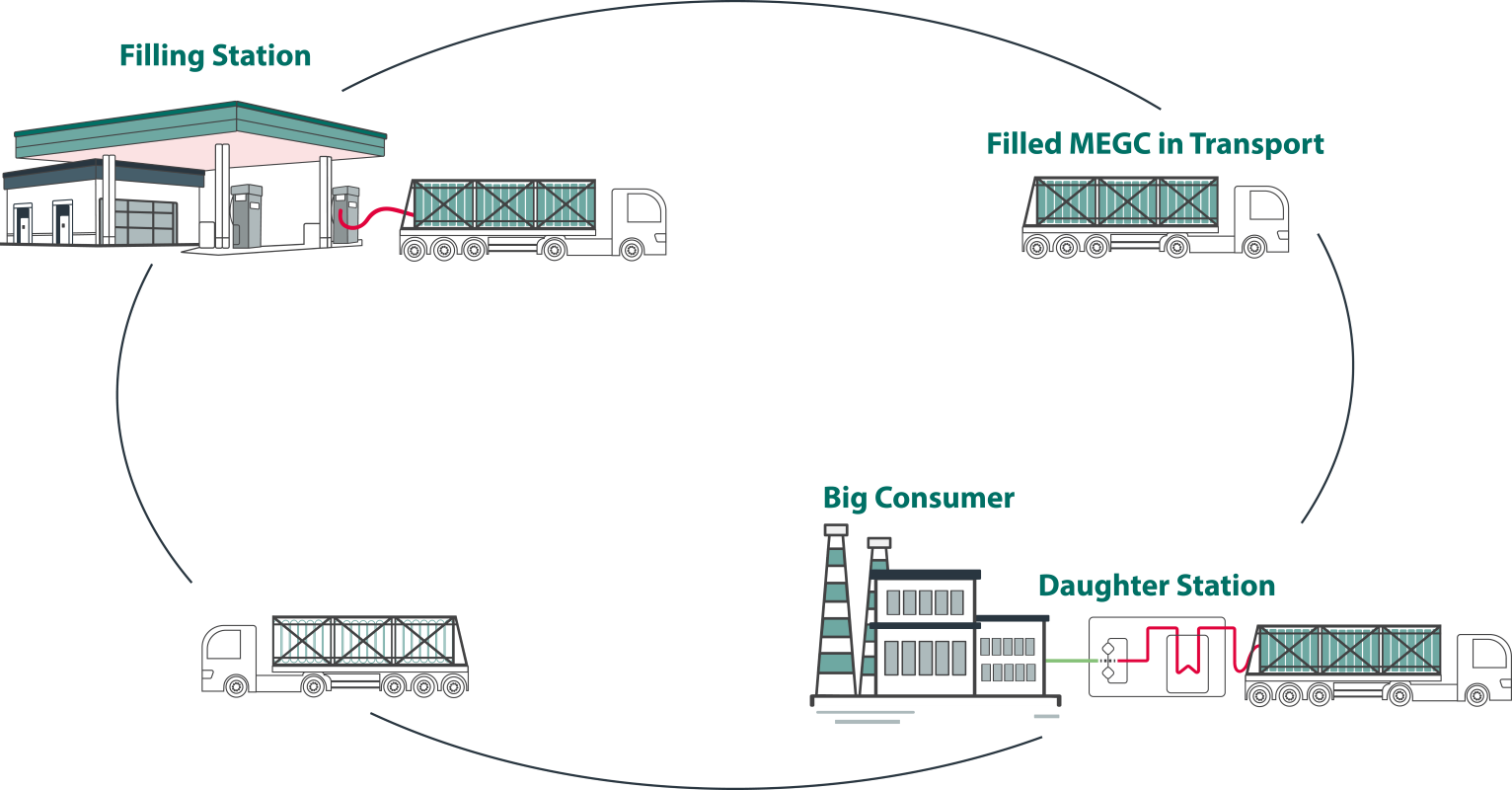

A multiple-element gas container (MEGC) with a semi-trailer enables the safe transport of high-pressure gases, including CNG, hydrogen, and biogas to any location, making it an alternative in areas without developed pipeline infrastructure.

The construction design and tank selection are tailored to meet medium, operational conditions, and technical specifications per customer requirements.

Key Specifications/Advantages

Suitable for all gas types (methane, biogas, hydrogen, associated gas, etc.)

Fast implementation

Functions as a “virtual pipeline” or mobile gas storage solution

Fully customizable to meet specific client requirements

Low operating and gas supply costs

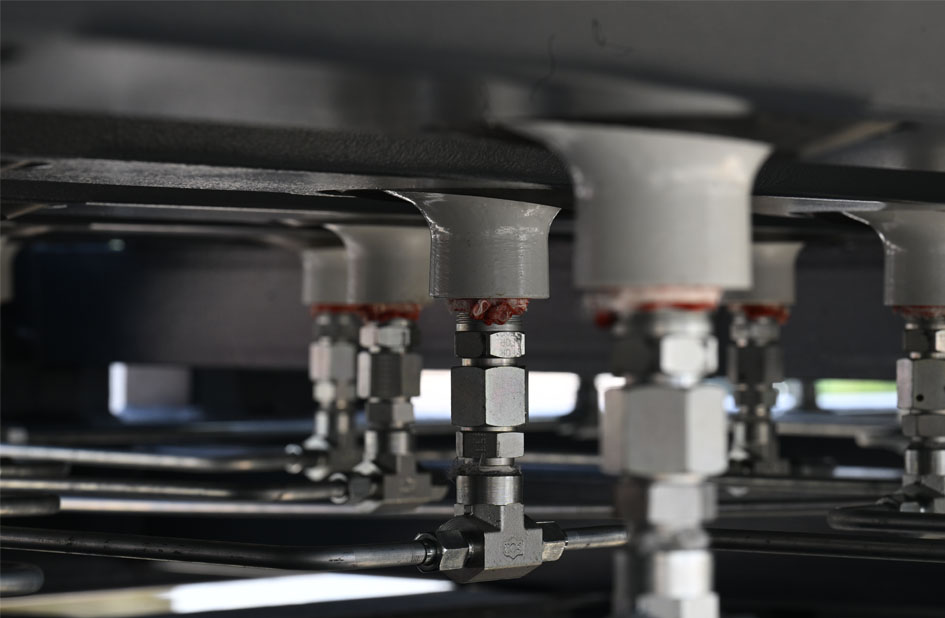

Main Components

- Double-neck mounted type II cylinders for better efficiency

- Customizable hydraulic capacity

- ADR/TPED certifications

- Optimized storage and transportation efficiency

Advantages

- Suitable for high-energy consumers where traditional gas pipelines are unavailable.

- Perfect for setting up daughter stations during the reconstruction of petrol stations.

- It can handle both methane and biogas efficiently.

- Reliable mobile storage solution designed for harsh road conditions.

- Designed for long-term storage and transportation of CNG use without any gas or liquid leakage.

Technical Specifications

- Type of cylinders: Type 2, or as per request

- Total capacity (nm3): 5700, or as per request

- Pressure operation (bar): 250

- Number of cylinders (pcs): 126, or as per request

- Brutto weight (kg): 27,000

- Cylinder position: vertical

*Specification valid for 30 ft MEGC container. MEGC units are available in a range of capacities and sizes, and can be tailored to meet specific customer requirements.

Gas Transportation to Any Location

Our solution is a versatile alternative for high-energy consumers, providing essential gas supply and transportation where traditional gas pipelines are unavailable.

It’s ideal for establishing daughter stations during the reconstruction of petrol stations, ensuring efficient gas distribution and storage.

Driving Efficiency and Cost Savings

Imagine a factory consuming between 50 and 2000 m3/h of gas, facing significant energy losses and production damages. As an illustrative case study, we successfully implemented a MEGC solution integrated with compressed natural gas and a reduction station, ensuring a stable and reliable gas supply.

The outcomes:

Losses eliminated, risks minimized, substantial cost savings, and enhanced production efficiency.

Secure Solution for Storing and Transporting High-Pressure Gases

Possible Collaboration Options

- Custom solution purchase: Tailor-made solutions to match your specific capacity requirements.

- MEGC unit rental: Flexible rental options for MEGC units.

Hrvatski

Hrvatski