PLEXOR® inspection system

Welcome to a new era of testing safety and pressure-reduction equipment! The PLEXOR® inspection system revolutionizes the approach to functional testing and maintenance of gas pressure regulation stations, offering high precision, accuracy, safety, and reliability.

Certification ensures that systems comply with industrial standards and are fully prepared to operate under a variety of working conditions. This is essential for maintaining a stable and secure gas network, guaranteeing both safety and reliability.

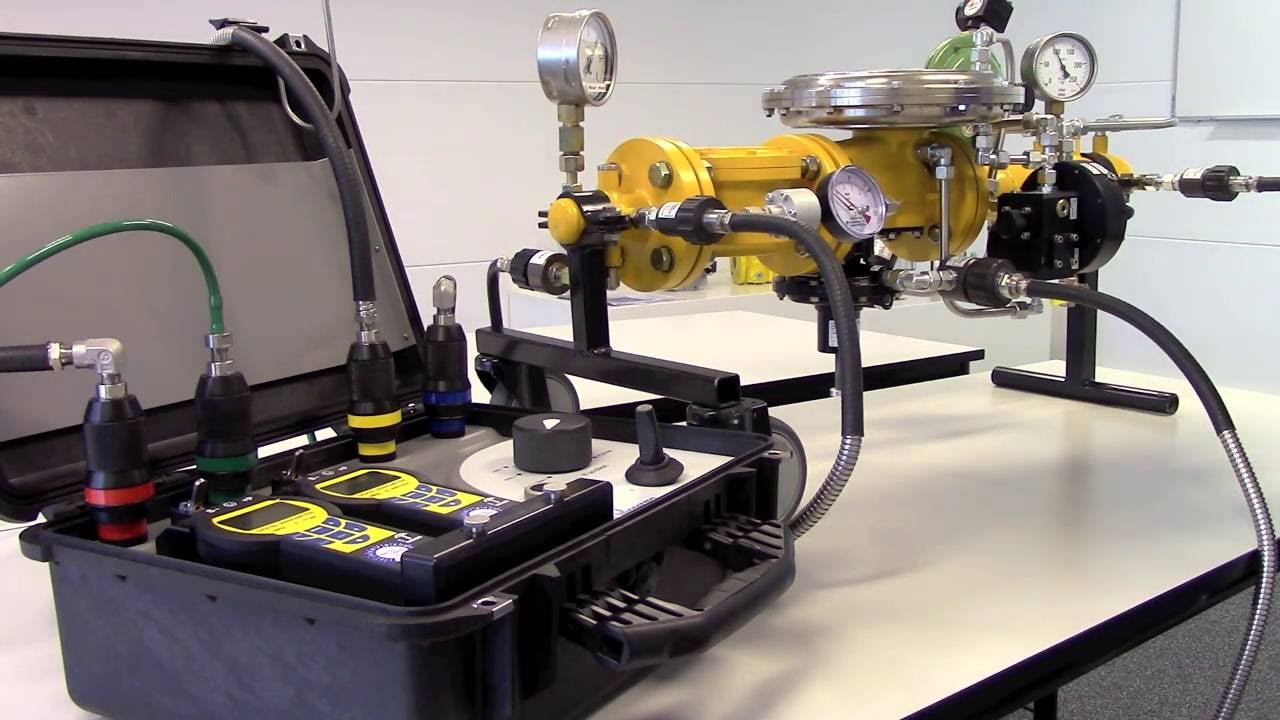

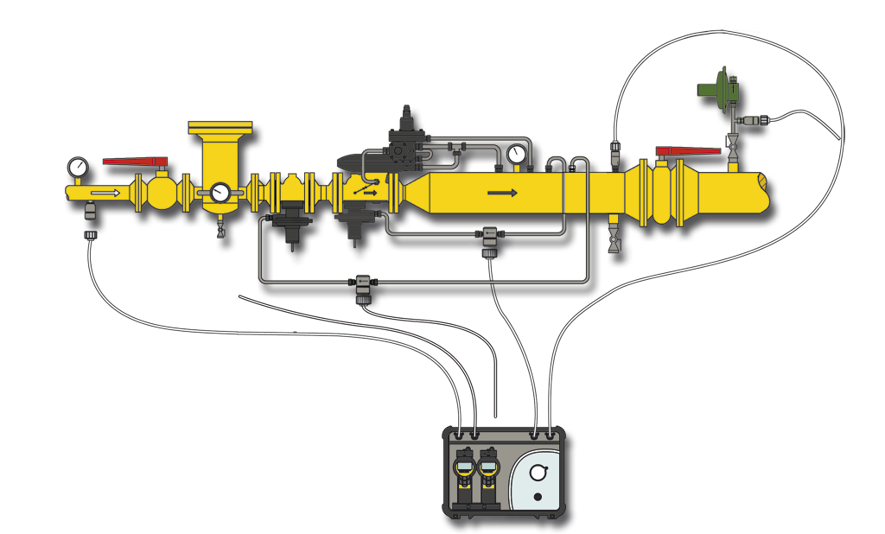

How does PLEXOR® work?

PLEXOR® enables detailed testing of key components in a pressure regulation station using an easy-to-operate mobile device. With its innovative design, testing is:

- Simple: The device connects via secure, permanently installed couplings.

- Reliable: Results are automatically stored on a handheld or portable computer, eliminating the need for manual data entry.

- Safe: System couplings prevent gas leakage and automatically return to their operational position.

An innovative solution for safety and functional testing of gas stations

Faster and more efficient inspections

Documentation and analysis

Identify trends and maintain systems in optimal condition.

Complete safety

Ensures operator independence and reduces human risk error, enhancing safety.

Reduced maintenance costs

Verify dynamic and static components without the need for replacement or recalibration.

Advantages

- High precision: Measurement frequency of 10 Hz for detailed and dynamic analysis.

- Error-resistant: Specifically designed couplings prevent incorrect connections.

- Environmentally friendly: Significant reduction of methane emissions during testing.

- Flexibility: Compatible with equipment from all manufacturers.

- No disassembly required: Component status can be determined without the need for dismantling.

Key components

- PLEXOR® Mobile testing device

- CONNEXION software package

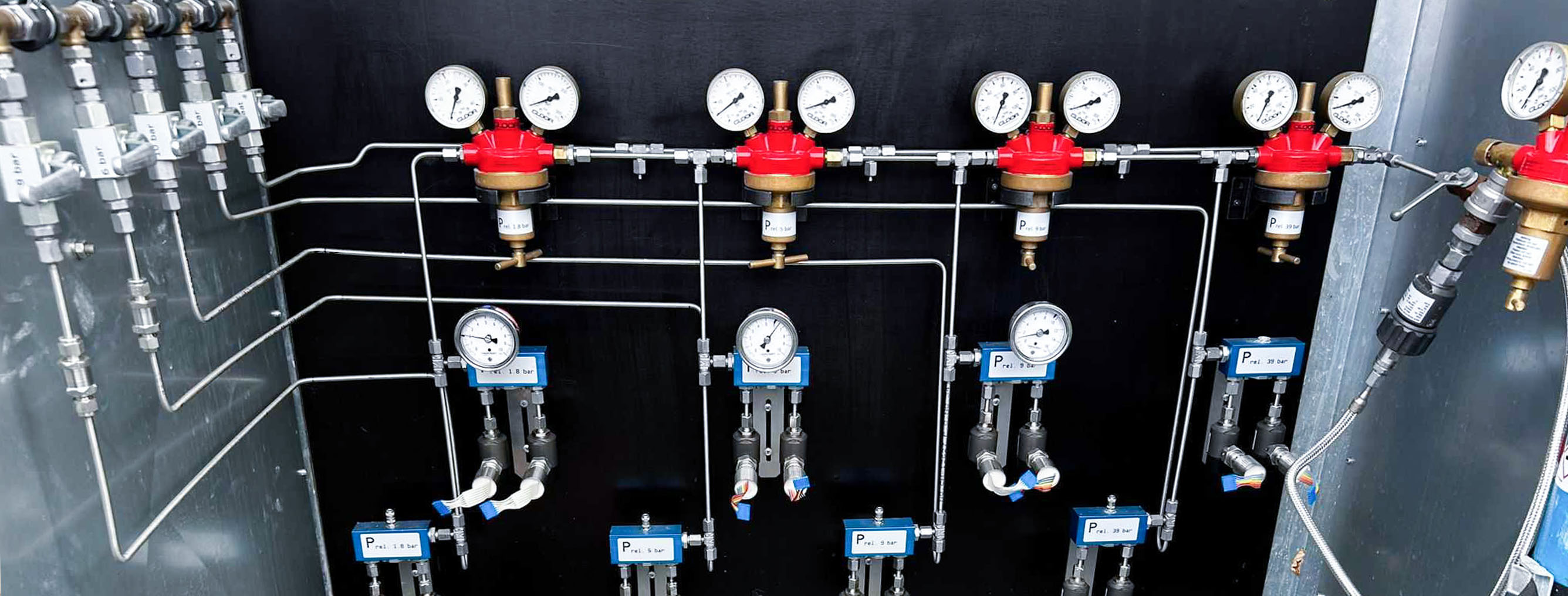

- Safety system couplings

Applications

PLEXOR® is the ideal solution for:

- Safety and functional testing of pressure reduction stations.

- Leak detection, dynamic performance checks, and visual inspections of gas equipment.

Hrvatski

Hrvatski