ILI & NON-ILI Inspection and Reporting

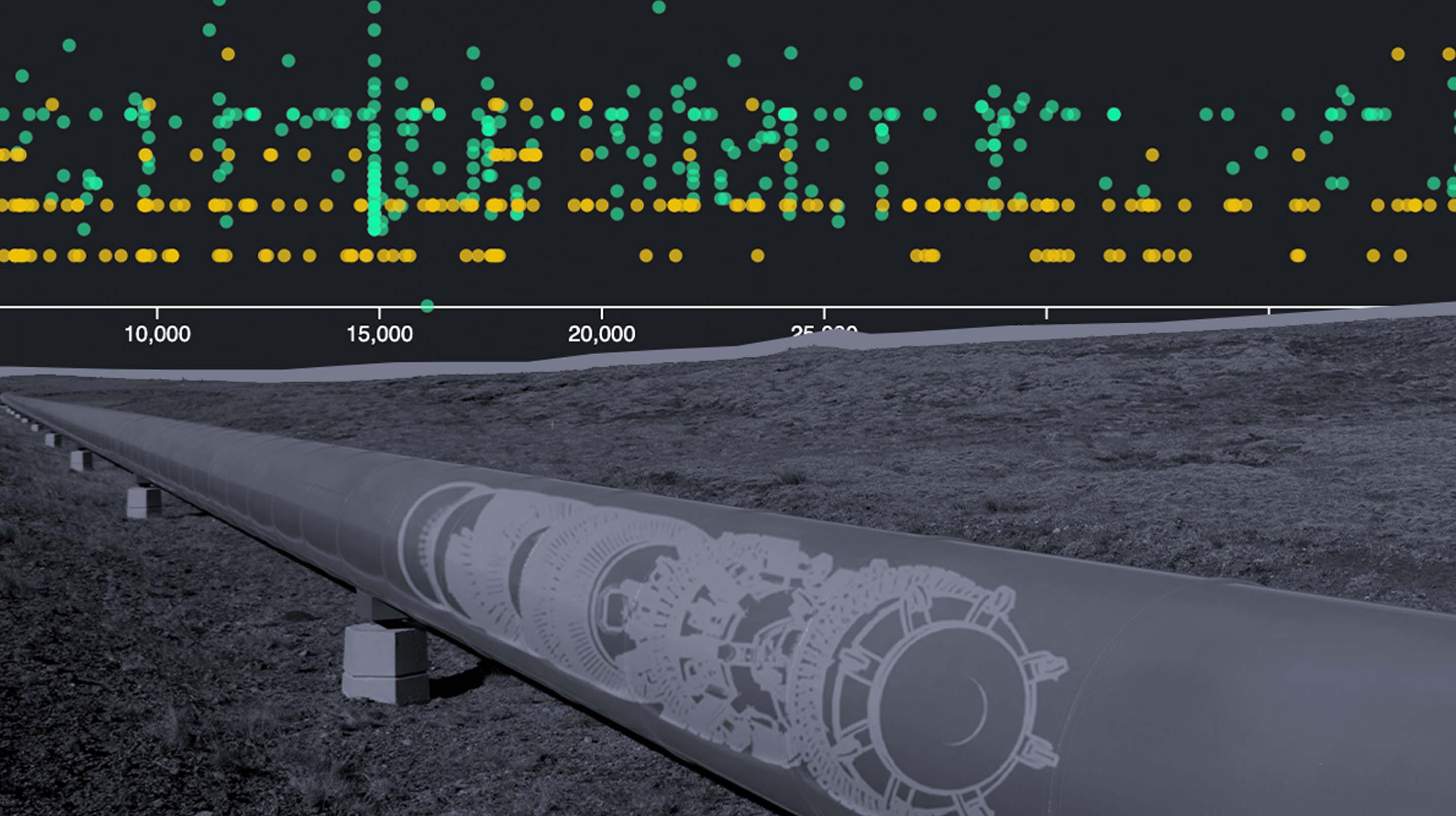

ILI (In-Line Inspection) and NON-ILI (Non-In-Line Inspection) services provide a detailed assessment of pipeline conditions.

ILI utilizes specialized devices inside the pipeline to detect corrosion, cracks, and other damages, while NON-ILI methods involve external inspection techniques, such as ultrasonic or magnetic methods, to identify potential issues.

Pipeline Inspection and Reporting: ILI and NON-ILI Methods

The safety, efficiency, and longevity of pipelines rely on regular inspections and early detection of potential damage.

Our ILI (In-Line Inspection) and NON-ILI (External Inspection) services provide a comprehensive evaluation of pipeline conditions, delivering precise data to support informed maintenance and repair decisions.

ILI Inspection – Internal Pipeline Examination

In-line inspection (ILI) utilizes specialized devices known as smart pigs that travel inside the pipeline. These advanced technologies enable:

- Corrosion detection – Early identification of issues before they become critical.

- Crack and deformation detection – Precise localization of structural weaknesses.

- Wall thickness monitoring – Enables proactive maintenance planning and ensures long-term pipeline integrity.

ILI technology delivers highly accurate data, including the size, shape, and location of potential damages, allowing for proactive risk mitigation and ensuring the safe and efficient operation of pipelines.

NON-ILI Inspection – External Examination Methods

NON-ILI methods are ideal for pipelines that are incompatible with internal inspection devices. These inspections utilize advanced external techniques, including:

- Ultrasonic testing – Measures wall thickness and detects corrosion.

- Magnetic Flux Leakage (MFL) – Identifies metallic imperfections and structural anomalies.

- Geophysical and visual inspections – Detects potential issues from accessible locations.

NON-ILI approaches provide a flexible solution for pipeline maintenance, allowing for comprehensive assessments without requiring internal access.

Why Choose Us?

- Expertise and technology: Years of experience combined with cutting-edge inspection technologies.

- Tailored solutions: Inspections customized to meet your specific requirements.

- Comprehensive reports: Clear analysis and maintenance recommendations.

Our mission is to ensure the safety and reliability of your pipeline system. Contact us for professional ILI and NON-ILI inspection services to safeguard the long-term integrity of your infrastructure.

Hrvatski

Hrvatski