High-Quality Pressure Equipment and Solutions

Our selection of filters, separators, and pressure vessels is engineered to meet the demanding requirements of industrial facilities, ensuring optimal efficiency, safety, reliability, and long-term performance.

Whether you need high-performance filtration, effective particle separation, or durable pressure vessels for storage, we deliver end-to-end design and manufacturing solutions, covering everything from process and structural calculations to the final product.

Products

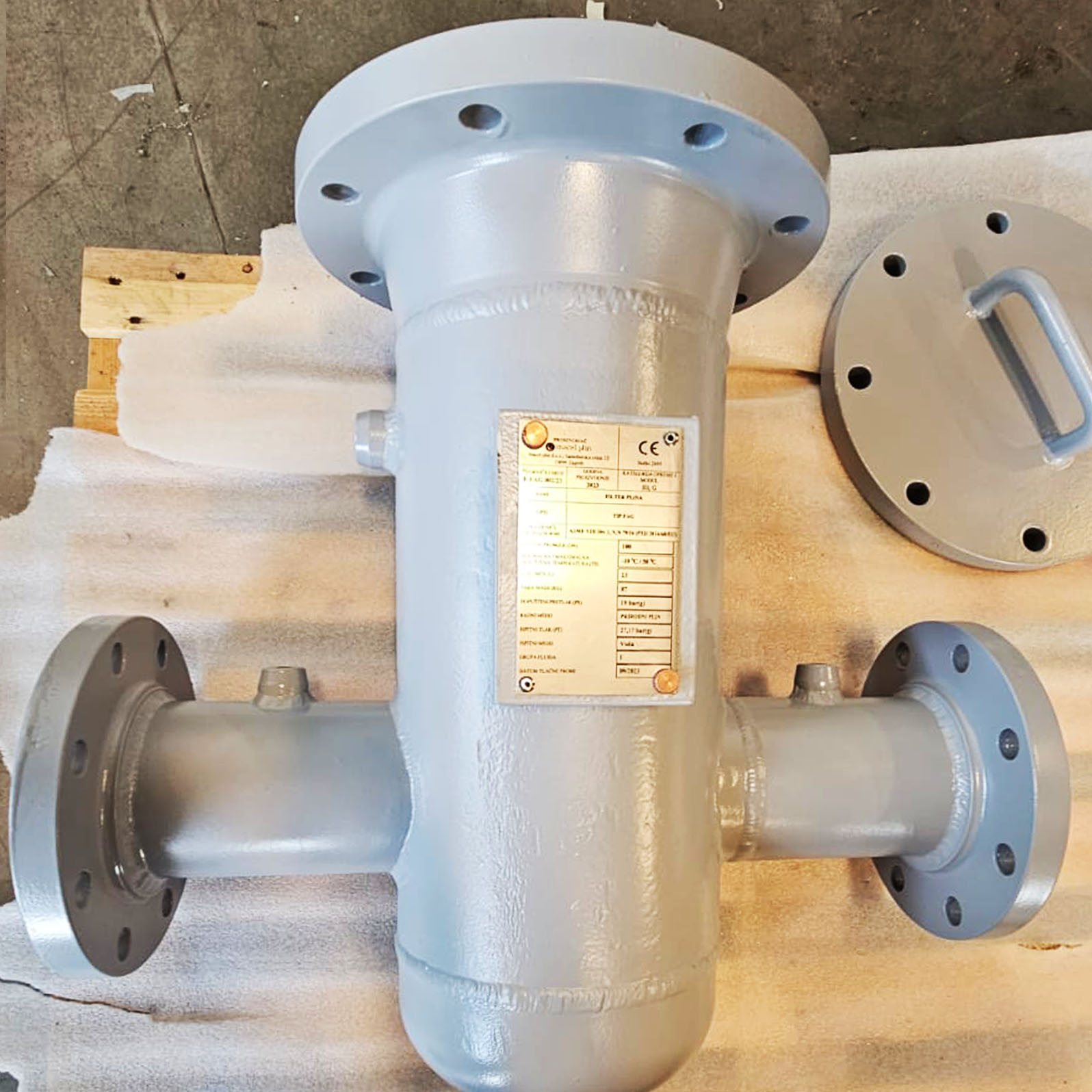

- Filters: Designed to purify air, gases, and liquids, they ensure high efficiency in removing impurities and can be tailored to meet specific application requirements.

- Separators: Efficient separation of liquid and gaseous phases and reduction of contamination risks. Designed for optimal performance in the oil, gas, chemical, and food industries.

- Pressure vessels: Engineered for the safe and reliable storage of liquids and gases, ensuring maximum pressure resistance.

- Heat exchangers: Designed for efficient heating and cooling of working fluids. We manufacture Shell and Tube heat exchangers in full compliance with TEMA R, ASME VIII, and EN 13445 standards.

Advantages

- High filtration and separation efficiency: Our filters and separators ensure precise impurity removal, optimized particle separation, and effective phase division, enhancing overall system performance and reliability.

- Safety and quality: All our pressure vessels are designed and manufactured in compliance with ASME VIII Div. 1, EN 13445, and AD 2000 standards. Acceptance of pressure vessels is conducted by a notified body in accordance with the PED 2014/68/EU directive.

- Durability and reliability: Premium-quality materials, such as carbon and stainless steel (selected based on specific requirements and operation conditions), combined with expert craftsmanship, ensure long-term durability and consistent performance without degradation.

- Versatile customization options: We design and manufacture heat exchangers from the initial process design phase through thermal and strength calculations to the final product, fully tailored to meet the client’s specific requirements.

Why Choose Us?

- Top-quality products: We utilize premium materials and proven manufacturing techniques.

- Technical support: We provide assistance and guidance at every stage, from product selection to installation and ongoing maintenance.

- Fast delivery: We guarantee prompt delivery along with all required certifications to ensure seamless operation and compliance.

- Experience and expertise: Our team of engineers has extensive experience and specialized expertise in the pressure equipment industry.

Hrvatski

Hrvatski