INTEGRATED SOLUTION

Pipeline Repairs Under Pressure at Working Conditions

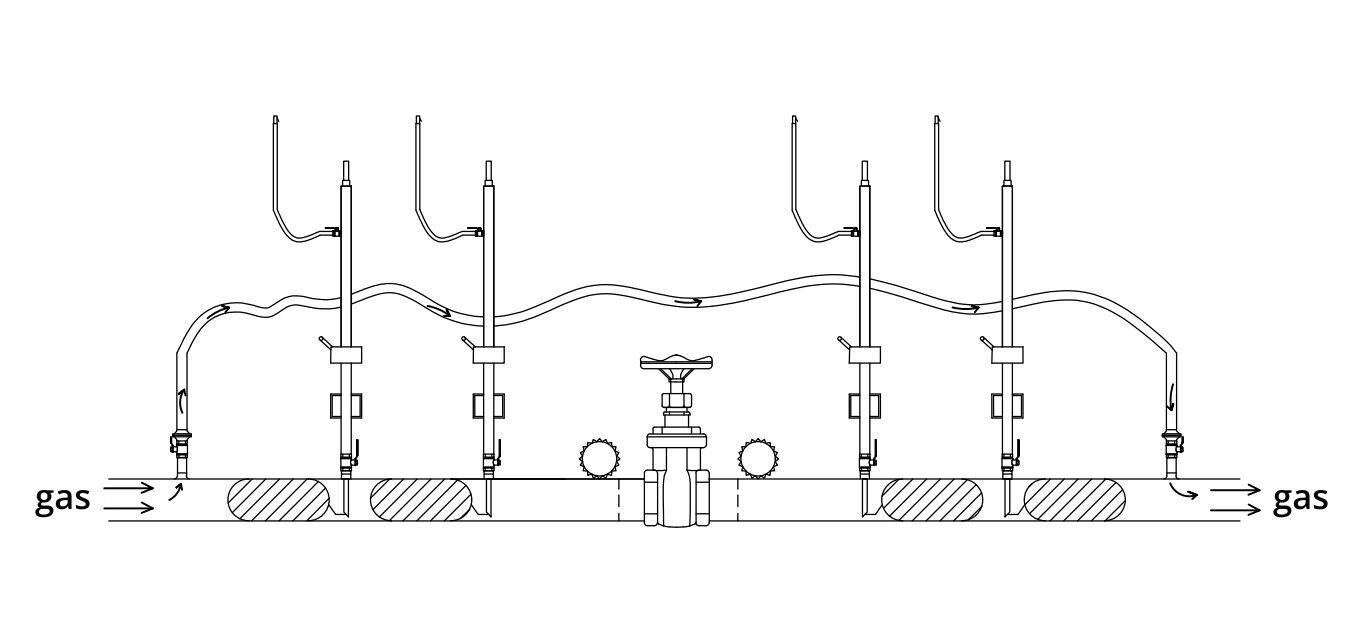

Ballooning is an innovative and environmentally friendly technique that isolates a section of the pipeline, allowing necessary maintenance or modifications to be performed without interrupting the gas supply to end users.

This technique utilizes a balloon to temporarily halt gas flow in a specific section of the pipeline, allowing for the safe execution of tasks such as valve replacement, installation of transition fittings, or pipeline repairs.

Ballooning Process

Welding of Weldolet:

Installation of the housing for the dome.

Hot Tapping:

Enables access without gas release.

Pipeline Cleaning:

Removes impurities to enhance safety and efficiency.

Balloon Insertion:

Deploys a balloon to isolate the pipeline section.

Inertization:

Replaces gas with an inert gas for improved safety.

Work Execution:

Includes repairs, replacements, or new installations.

Balloon Removal:

Restores the system to its original operating state.

Plug insertion:

Ensures final securing and integrity of the pipeline system.

Hot Tapping

Hot Tapping is a specialized technological process that allows for the installation and welding of branch connections onto an existing gas transmission pipeline without interrupting gas flow.

This method allows for the safe and efficient addition of new connections to the system without requiring a shutdown or pipeline depressurization, preventing losses and ensuring continuous operation.

Advantages of Ballooning with Bypass Installation

- Enables pipeline work without supply interruption.

- Prevents activation of system lockout mechanisms.

- Eliminates gas release into the atmosphere (Reduces operational costs by preventing gas losses and minimizes environmental impact through lower emissions).

Technical Specifications

- Maximum pressure: 4 bar

- Minimum diameter: DN 80 (additional equipment available for smaller diameters)

- Maximum diameter: DN 200

- Materials: Steel and PEHD pipelines

Note: Additional equipment can be supplied to meet higher demands for specific customer requirements.

Application

Ballooning is applied in situations that require pipeline intervention, such as:

- Installation or replacement of valves.

- Replacement of pipeline sections.

- Installation of steel/PEHD transition fittings.

Safe, Eco-Friendly, and Uninterrupted Gas Supply

Ballooning is the ideal solution for safely conducting pipeline work in urban areas or regions where maintaining a continuous gas supply is critical.

Hrvatski

Hrvatski