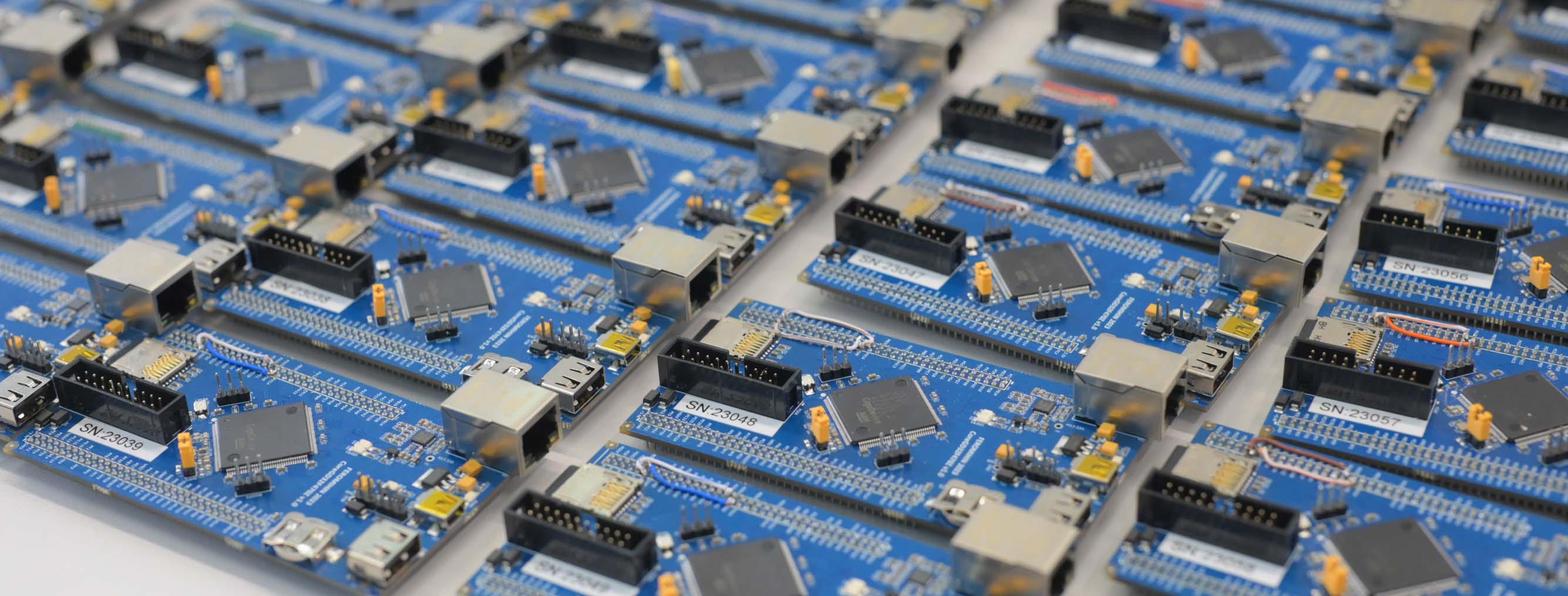

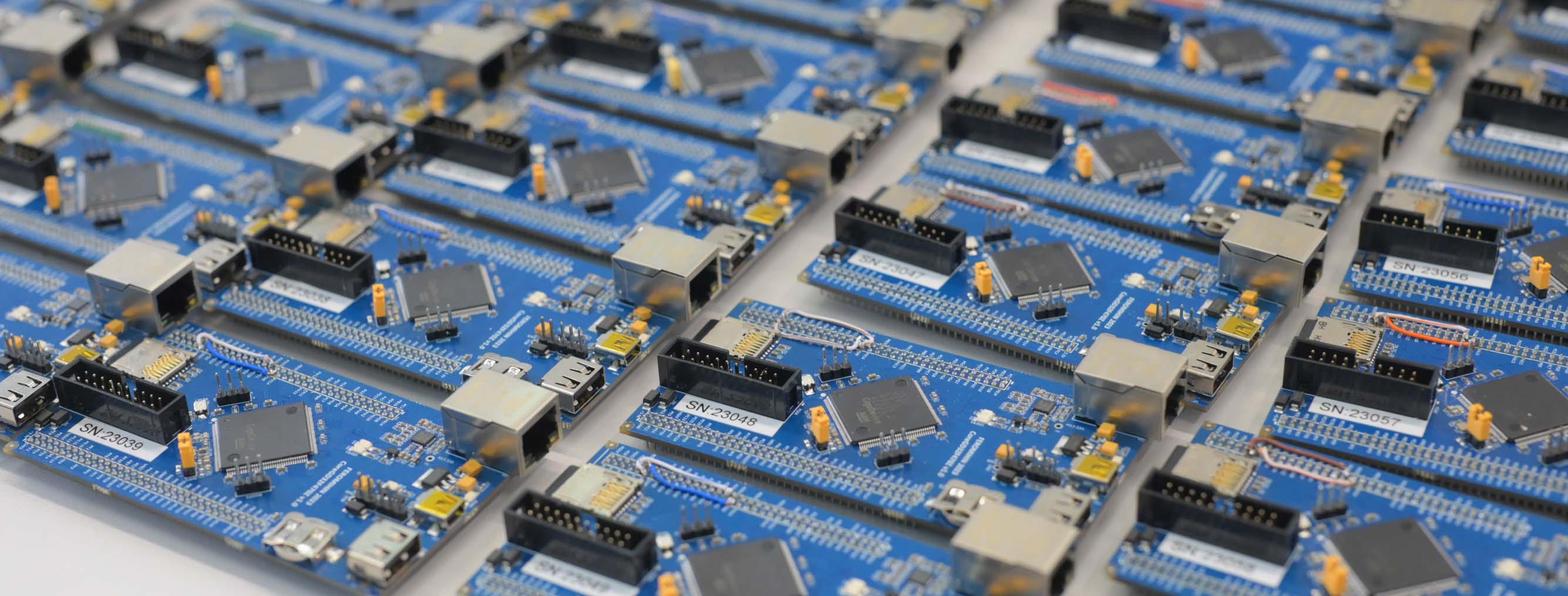

Automatic Assembly of Components

At PICO FLOW CONTROLS d.o.o., we specialize in PCB board assembly, focusing on assembling electronic components onto printed circuit boards (PCBs).

PCB Assembly includes a wide range of electronic components, such as surface-mounted devices (SMD) and through-hole technology (THT) components.

These systems ensure the automation, monitoring, and control of critical operations. The assembly process integrates both automated and manual tools to guarantee precision and high-quality results.

PCB Assembly

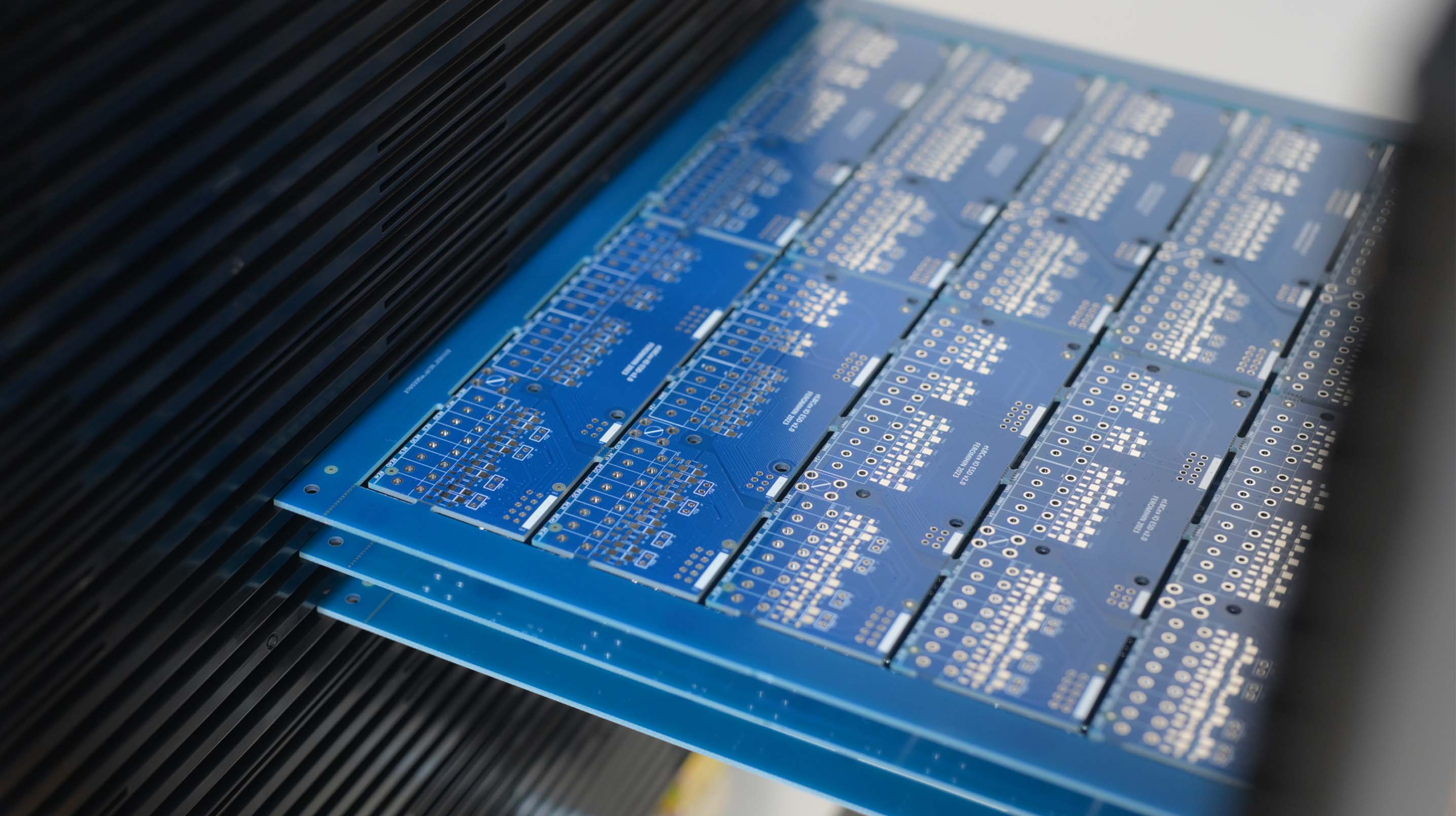

PICO FLOW CONTROLS d.o.o. provides PCB manufacturing and assembly services customized to support every stage of your product development process:

- Prototype PCB assembly: Enables the rapid production of prototypes to evaluate PCB design functionality before ordering a larger batch.

- Small batch PCB assembly: Optimized for specialized applications requiring limited quantities of various boards.

- Large batch PCB assembly: We specialize in high-volume PCB production, maintaining the same precision and attention to detail as with smaller batches.

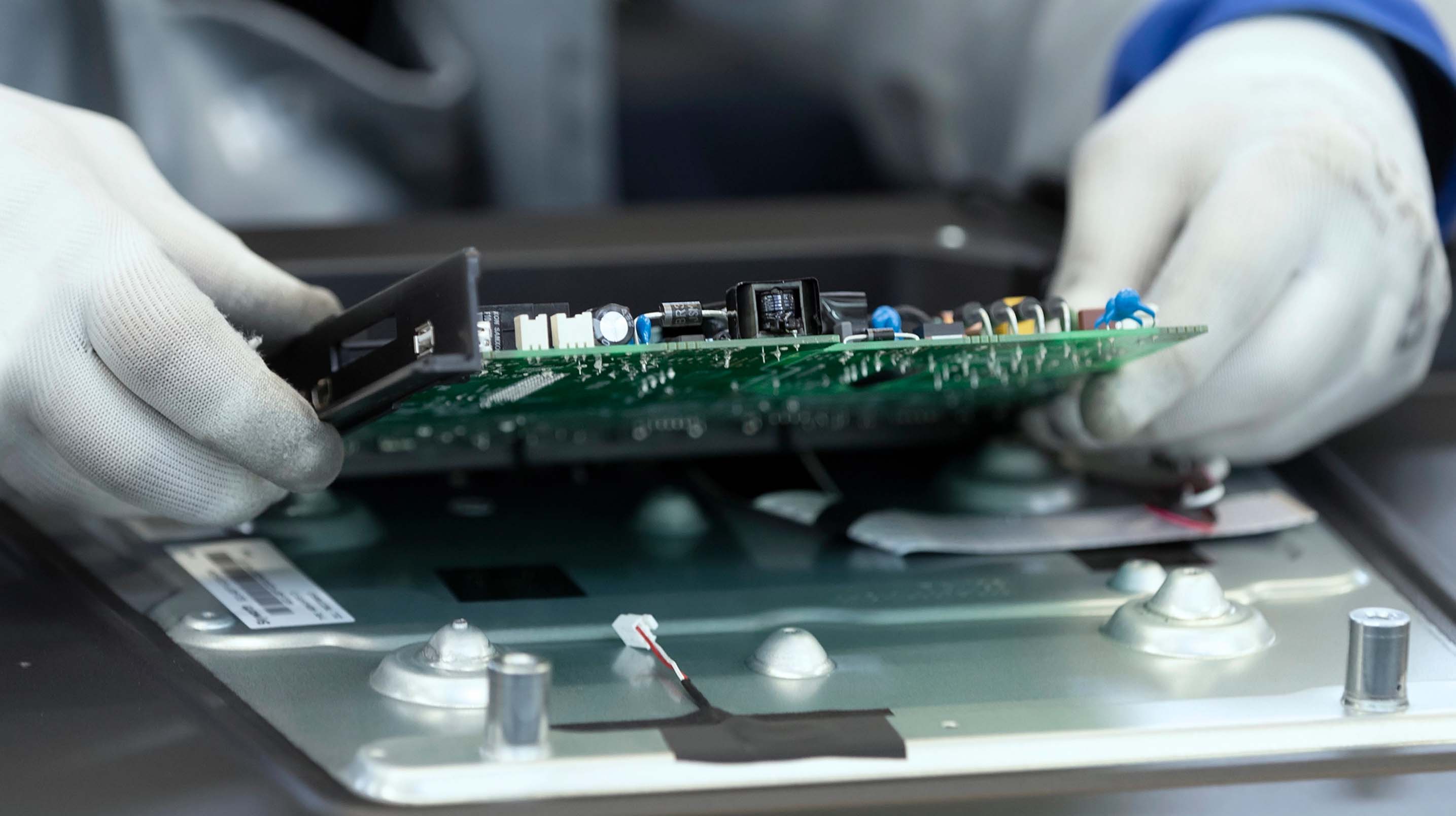

Assembly on Both Sides

We offer dual-side PCB board assembly, allowing components to be mounted on both the top and bottom sides of the PCB.

This allows for more complex designs and higher component density, ensuring maximum performance and reliability in your product.

Technical Specifications

- Material: High-density polyethylene

- Mesh thickness: 10 mm

- Maximum temperature: 90°C

- Chemical resistance: High

Functionalities

- Two machines, each with 160 8mm feeder positions, totaling 320 8mm feeder positions

- Minimum PCB size: 50 x 50 mm

- Maximum PCB size: 510 x 390 mm

- Maximum operating speed: 2 x 35,800 CPH/machine = total 71,600 CPH/system (CPH = components per hour)

- Placement accuracy: ±40 μm

- Minimum component size: 01005″ (0204)

- Maximum component size: 120 x 90 mm or 150 x 25 mm

- Maximum component height: 28 mm

Latest SMT and THT Equipment

We specialize in assembling PCBs using the latest technology and state-of-the-art machinery.

Before final implementation, we conduct rigorous visual and technical testing, ensuring a fully functional, high-quality end product.

Hrvatski

Hrvatski